Many people don’t realize the time and process denim goes through before it gets to the store. During the dying process, dye is introduced into the fabric to create the color, and the fabric is spun around a loom where the dye dries. The denim clothing created through this process is called raw denim. After the fabric dries, it’s stretched, pulled tight, and then returned to the production line to be woven. The original creator of denim was Levi Strauss. Mens levi jeans from EJ Menswear are some of the best.

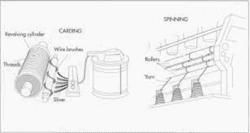

During weaving, the weft (the backside) of the denim is separated from the backside (the front). This further strips the yarn of material, which creates a strong, but light piece of denim clothing. While this may seem relatively simple, there are many tiny elements that go into making the final product, such as the quality of the stitching and the fading of the dye. When the denim clothing is completed, it is cut and shipped to a manufacturer, where it is finished and ready to be sold. While some jeans are mass-produced, other companies focus on creating a special type of denim, such as the Japanese auto denim, which is handmade.

The process used by Japanese auto jeans manufacturers is more complicated than the way it’s created in America. During the weaving process, the exact dimensions of each jean are carefully controlled to create the right thickness and weight. Once the material is ready to be sold, it must be washed and ironed at a temperature of over 400 degrees Fahrenheit, which gives it a faded finish. To learn more about how is denim created and its unique qualities, visit the Denim Hub website today.